All this snow is the main reason I decided to write an update for the web page today. A plow has not come down my street yet, and I am pretty much stuck at home. If I had my winter tires on I might stand a chance, but things have been a little busy, and I haven't managed to get around to putting them on yet.

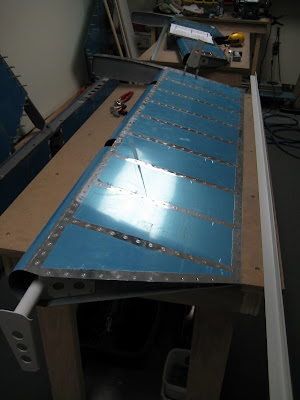

Since I was sitting at home anyways I decided I might as well make an attempt at putting on those winter tires. First step was to clean out my garage so I have a place to work... This ment moving the airplane pieces I am storing into my living room. In my mind nothing says Bachelor Pad like airplane pieces sitting in your living room.

So my car made it into the garage, and I will let it warm up and dry off a bit before I switch up the tires.

As for the hanger it looks like we are in for a bit of a break. We still need to finish wiring up the lights, and install some weather stripping around the main door before we can call the project complete, but Scott is off to New York this week-end, and I am heading back to Regina on the 16th, so it looks like this may be it until after Christmas.

I think Scott and I are both looking forward to leaving the hanger project behind, and getting back to building our airplane in the new year.

So for the moment, Merry Christmas, and Happy New Year.