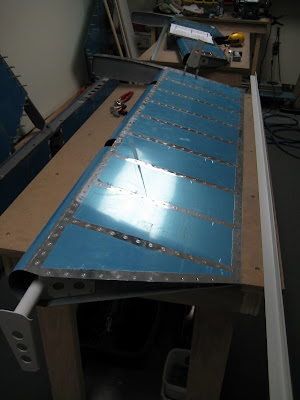

Well, if the title didn't give it away we spent most of today installing platenuts on the left wing main spar. Every platenut has 2 rivets which isn't really all that much but when you consider that we must do the following steps for every platenut:

- match drill the rivet holes (to get them to the correct diameter

- machine countersink the 2 rivet holes

- deburr all rivet holes

- spot prime where we countersank for the rivets

- rivet the platenut into place (2 rivets)

- countersink for the screw

- spot prime the screw countersink

It is actually a lot of work (we installed 76 platenuts today).

It was a little tedious but we completed the installation of all the platenuts and started working on the tie down bracket (used to tie the wings down to the ground when parked). Before we quit for the day we layed out the part and tapped a 3/8x16x1" hole.

Scott squeezing some platenuts.

Darren squeezing some platenuts.

A sign we were not treating our hand squeezer as nice as we should have been.

Scott match drilling.

Scott squeezing some more platenuts.

A close-up of some platenuts from the back.

A close-up of some platenuts from the front.

Scott tapping the tie down bracket.